632 - American Crystal 2023 Cercospora Control Recommendations

Timing & Tank-mixing Fungicides to Optimize Cercospora Leafspot (CLS) Control and Resistance Management.

For CLS control and resistance management, ACSC’s fungicide tank-mix recommendations combine 2 different modes of action pairing a translaminar/systemic fungicide with a contact fungicide.

- Exception is when EBDC is alone in the 5 & 6 spray programs

- There is no documented resistance to EBDC fungicides

Timing the start of your Cercospora Leaf Spot Spray program.

- It can take 5 to 21 days for spots to appear after Cercospora infects the leaf.

- In 2022, American Crystal worked with Dr. Wyatt, Cercospora Epidemiologist at the Fargo USDA, to analyze sugarbeet leaf samples for the presence of Cercospora DNA in leaves that had no visual Cercospora spots.

- Each of American Crystal’s Agriculturists (24) took 7 sugarbeet leaf samples weekly (168 total/week) from June 13th – July 11th.

- By July 7th, 100% of the locations monitored, North to South, were positive for the presence of CLS DNA in the leaf with no visual spots present.

- This is even considering that 2022 was a late planted year & had a dry environment.

What does this mean for timing Cercospora fungicide applications?

- Start early and stay on track.

- Fungicides are protectants and are not curatives, use them as such.

- Limit CLS infections and year-end disease severity with proactive fungicide applications to protect the sugarbeet leaves before infections can occur.

- Factors contributing to a conducive environment for CLS development:

- Moderate to severe Daily Infection Value’s (DIV’s).

- Sugarbeet leaves 4” from closing the row.

- Free moisture on leaves (rain/dew).

- Be prepared to start as early as the end of June to the 1st week of July.

- ACSC data shows in general that recoverable sugar/acre and revenue/acre are optimized when starting fungicide applications in this time frame.

- Initial fungicide timing for both CR+ and non-CR+ varieties are the same.

- In CR+ varieties, the timing of the 1st two fungicide applications is most important to achieve optimum crop potential.

Work with your Agriculturist for proper timing based on environmental conditions and crop development.

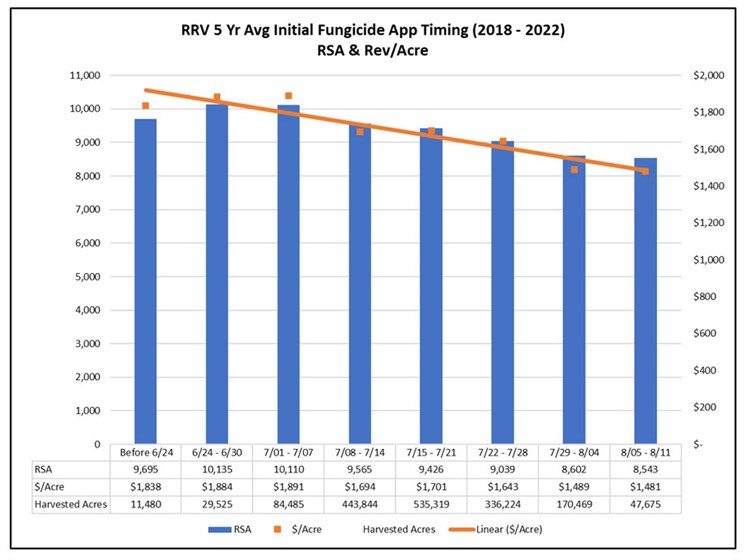

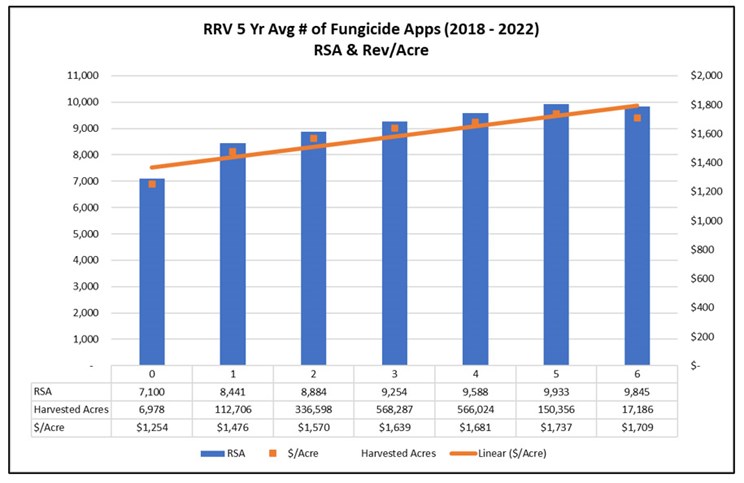

RRV Initial CLS Fungicide Application and # of CLS Fungicide Applications

The below charts are compiled from data collected by American Crystal Agriculturists from growers on their Cercospora fungicide application programs from 2018 – 2022 for the Red River Valley.

- Your Agriculturist has these same charts for their factory district and their growing area.

- The trends are the same for these as compared to the Red River Valley.

The charts below show increases in recoverable sugar/acre and revenue/acre with earlier initial fungicide applications and with additional fungicide applications.

Monitor CLS Daily Infection Values (DIV’s)

2023 ACSC Cercospora Leaf Spot Fungicide Program

Tips for Maximizing Cercospora Leafspot Control

- CLS variety rating – CLS control should improve with a better CLS variety rating. However, this may not equate to fewer fungicide applications.

Variety Selector CLS Ratings - Daily Infection Values – Monitor Daily Infection Values (DIV’s) and weather forecasts for timing initial and following fungicide applications @ NDAWN

- Timing of fungicide program – Start program once rows are 4” from closing and coinciding with Moderate to Severe DIV’s. Start early and stay on track. Cercospora Leaf Spot can appear 5 to 21 days after spore infection. Fungicides are protectants, being proactive by applying fungicides ahead of infection limits the development of Cercospora leaf spot.

- Full rates – In tank mixes utilize full application rates of each tank mix partner, following label recommendations.

- Spray intervals – The time interval between applications should not exceed 12 days, plan best as possible around adverse weather conditions (rain, wind, hail). For EBDC’s alone follow a 7-day spray interval.

- Aerial application – If too wet for ground application, stay on schedule with an aerial application.

- Glyphosate tank mixes – Are not recommend with CLS fungicide applications since optimum water volume requirements are different for glyphosate and CLS fungicide applications as the target pests are not the same.

- Pre-Pile & Fungicide Pre-Harvest Intervals – Be aware of each fungicide’s Pre-harvest Interval and how that may impact pre-pile harvest plans. Adjust your fungicide spray program accordingly.

- Water volume – CLS fungicides need excellent coverage to protect the sugarbeet leaf surface. To achieve this requires a minimum of 15 to 20 gallons of water per acre. More water is better!

- Pressure – High pressure applications at 80+ psi provides improved leaf coverage depending on the spray tip chosen.

- Spray nozzles/tips & droplet size – Using nozzles that will produce Medium droplet sizes of 250–350µm (microns) is optimum for fungicide applications. Utilize nozzle manufacturer’s recommended application pressure to operate within this range. Use proper spray boom height above crop canopy depending on chosen spray nozzle degree angle for best coverage.

- Tank mixes – All fungicide applications should contain more than one chemistry or mode of action (MOA). Only exception would be EBDC’s. Tank-mixing fungicide MOA’s and rotating MOA’s are paramount. Using only a single fungicide, MOA, increases resistance development pressure to that fungicide. Single fungicide applications may “get you by” but will increase and compound resistance to fungicides on your farm and surrounding neighbors. Utilizing all available fungicide chemistry wisely is vitally important for current fungicide options today and tomorrow. Any tank mix should be sprayed out as soon as possible, with agitation, do not allow mix to sit overnight, spray tank out completely, and rinse sprayer (all lines and tank) with clean water daily.

- Water temperature – Warm water is best for dissolving & mixing fungicides. Pre-warm water in dark bulk tanks a few days prior to use, sunlight aids in warming the water.

- Jar test – If in doubt about a tank mix, run a jar test to see if combination is compatible before loading sprayer.

- Scout fields –during the growing season to evaluate how your fungicide spray program is working.

Wales tank mixing order for Pesticides

- Wettable powders & dispersible granules

- Agitate tank to mix thoroughly

- Liquid flowables & suspensions

- Emulsifiable concentrate formulations

- Surfactants & Solutions

CONTACT YOUR AGRICULTURIST

Contact your American Crystal Agriculturist for the most up-to-date information on issues affecting sugarbeets in your area.