584 - Harvest Strategies to Maximize Profit

On Farm Profit from sugarbeets is improved if the crop is harvested and stored properly prior to processing. Objectives of proper harvesting include: (1) minimizing harvest losses; (2) delivering minimum tare; (3) complete removal of leaf and petiole material; (4) delivery of frost free roots to storage piles and (5) placing beets in storage at root temperatures of 55 degrees Fahrenheit or less. Careful harvesting, proper beet storage, and efficient processing are complex interrelated operations. Meeting these objectives will maximize profit!

Full Stockpile Field Selection

- Harvest low yield potential fields first (disease, weeds, root aphids, other)

- Harvest poorly drained fields early

- Harvest low plant population fields early

- Harvest tonnage type varieties last, let quality increase

- Harvest high N fields last so quality improves

- Harvest late planted fields last or as late as possible

- Harvest high sugar type varieties early

- Harvest heavy soil types first

High Speed Costs; Slow Speed Pays!

Excessive travel speed with both harvesters and defoliators result in greater harvest losses, poorer defoliation and lost revenue per ton and per acre. Slow down and increase on-farm-profit.

Table 1: Effects of Defoliator Ground Speed on Sucrose Content and Beet Payment. Larry Smith, U of MN

| Defoliator Speed (mph) |

Sucrose (%) |

SLM (%) |

Rec. Sucrose (lb/T) |

Revenue ($/T)* |

|---|---|---|---|---|

| 2 | 19.66 | 1.62 | 360.7 | 65.54 |

| 3 | 19.40 | 1.7 | 353.9 | 63.50 |

| 4 | 19.12 | 1.81 | 346.0 | 61.15 |

| 5 | 18.90 | 1.85 | 340.9 | 59.59 |

* Based on American Crystal payments for 2007-2011.

Tips for Successful Defoliator Operation

- Slow down - excessive speed is costly, operate at 2-3 mph.

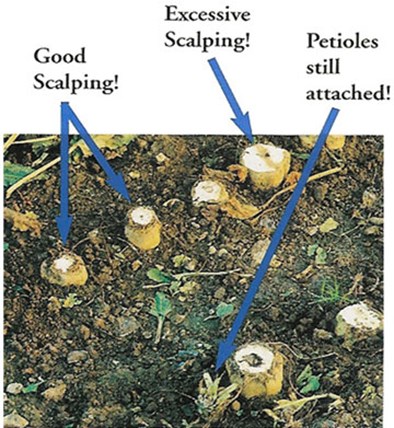

- Poorly adjusted and dull scalping knives cause increased yield loss.

- Remove all petiole and leaf materials - see figure below.

- Adjust defoliator settings for each field or variety to eliminate knocking beets out of the row.

- Don't use all rubber flails after a frost.

- Take time to train defoliator operators.

- Change flails as needed.

- Hire a full time defoliator operator.

- Minimize root and crown breakage.

- Sweep leaf trash away from the row with rear flails to facilitate lifting and minimize harvest loss.

Tools to Minimize harvest Losses

American Crystal Sugar Company's "Harvest Loss Team" has put together a tool box of useful items to aid growers to harvest the crop better than ever. Utilize those tools most likely to be of benefit in your operation. Most of these tools are available at www.crystalsugar.com, then click on Ag Tools and go to Ag Calculators or Harvest under Agronomy Gold Standards.

Table 2: Effect of speed of harvester operation on sugarbeet yield and quality, 1992 and 1992. Dexter, Cattanach, Kiefer.

| Harvest Speed (mph) |

Yield (T/A) |

Sugar (%) |

SLM (%) |

RSA (lbs) |

Rev/A * ($) |

|---|---|---|---|---|---|

| 3-4 | 17.2 | 18.2 | 1.2 | 5848 | 1020 |

| 5-6 | 16.2 | 18.2 | 1.3 | 5476 | 951 |

| Slow Speed Advantage | 1.0 | ----- | .1 | 372 | 69 |

* Based on American Crystal payments for 2007-2011

Reduced harvester speed resulted in $69/acre greater revenue.

Just one poorly defoliated beet in 10 with 3 inches of petiole can reduce revenue by up to $10/A or more.

Contact your agriculturist for assistance with any problem discussed in this Ag Notes issue.