514 - Crop: Finish Successfully Crop: Plan Ahead

Late August, September and October means harvest of one crop and implementing plans to successfully raise the next one. Attention to all the basic details can make the difference between profit and loss for both crops. The Ag Department "Harvest Team" has provided many educational resources to maximize harvest efficiency

American Crystal Sugar Company's "Harvest Loss Team" has put together a toolbox of useful items to aid growers to harvest the 2008 crop better than ever. Utilize those tools most likely to be of benefit in your operation. Most of these tools are available at www.crystalsugar.com, then click on Ag Tools and go to Ag Calculators or Harvest under Agronomy Gold Standards.

Field Selection Harvest Strategies to Maximize Profit

Prepile Harvest Strategies

- Harvest high sugar content fields first - especially with high yields too

- Send samples to the EGF lab to check crop quality before harvest

- Avoid high N fields due to low sugar percent

- Deliver entire high quality fields versus opening on headlands, ditches, or other poor areas to maximize prepile payment

- Scalping improves quality of low sugar fields that must be harvested

- Avoid fields with moderate to severe disease problems

- Avoid low plant population fields

- Avoid replanted fields for pre-pile

- Coarse textured soil type fields often have low sugar

Full Stockpile Field Selection

- Harvest low yield potential fields first (disease, weeds, poor stands, other)

- Harvest poorly drained fields early

- Harvest low plant population fields early

- Harvest tonnage type varieties last, let quality increase

- Harvest high N fields last so quality improves

- Harvest late planted fields as late as possible

- Harvest high sugar type varieties early

- Harvest heavy soil types first

Tips for Successful Defoliator Operation

- Slow down - excessive speed is costly, operate at 2-3 mph

- Poorly adjusted and dull scalping knives cause increased yield loss.

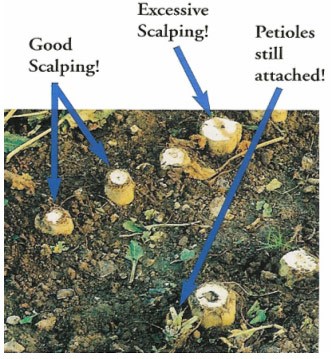

- Remove all petiole and leaf materials - see figure below.

- Adjust defoliator settings for each field or variety to eliminate knocking beets out of the row.

- Don't use all rubber flails after a frost.

- Take time to train defoliator operators.

- Change flails as needed.

- Hire a full time defoliator operator.

- Minimize root and crown breakage.

- Sweep leaf trash away from the row with rear flails to facilitate lifting and minimize harvest loss.

Table 1. Effect of speed of harvester operation on sugarbeet yield and quality, 1991 and 1992. Dexter, Cattanach, Kiefer.

| Harvest Speed (mph) | Yield (T/A) | Sugar (%) | SLM (%) | RSA (lbs) | Rev/A ($) |

|---|---|---|---|---|---|

| 3-4 | 17.2 | 18.2 | 1.2 | 5731 | 677 |

| 5-6 | 16.2 | 18.2 | 1.3 | 5475 | 635 |

| Slow Speed Advantage | 1.0 | ----- | .1 | 256 | 42 |

Reduced harvester speed resulted in $42/acre greater revenue. Reduced acres in 2008 should enable growers to slow field harvest operations and still complete harvest on-time.

N Credits from Beet Tops Very Valuable

There is "gold" in those beet tops for the taking. Research by Dr. John Moraghan and Larry Smith documented value of N in tops in the 1990's. See the example of beet top N value in Table 2.

| N Source | N Credit * (lbs) | N Value/Acre with Urea at $750/Ton |

|---|---|---|

| Yellow Beet Tops | 0 | 0 |

| Yellow Green Beet Tops | 15 | $12 |

| Light Green | 30 | $24 |

| Green | 45 | $36 |

| Very Green | 60 | $48 |

* Conservative nitrogen credits to ensure maximum 2009 crop yields after beets.

Just one poorly defoliated beet in 10 with 3 inches of petiole can reduce revenue by $10/A or more.